How to choose a glass sealant?

In everyday life, construction and even when repairing a car, sometimes you have to put a window, repair glass, repair a transparent plastic part. At the same time, an important task is to seal the joints of dissimilar surfaces.

The hard putty, so popular in the recent past, is confidently giving way to modern elastic pasty materials. Now more and more often, if necessary, to repair or install a glass product, specialized sealants are used in convenient packaging. When this is achieved the solution of two main tasks: the mechanical connection of parts and sealing the junction of different materials.

Purpose

For sealing windows and mounting window frames, window sealants are widely used. It is known that the heat from the house largely goes through the window openings and frames. The use of sealants for sealing window joints can significantly reducethis kind of loss.

Types and characteristics

It is especially possible to select drugs on cyanoacrylate basis. They are widely used in the repair of transparent products not only from glass, but also transparent plastics. In addition to the acrylic-based monomer itself, it can also contain various additives to increase resistance to weathering, elasticity, and the like.

Another group is polymeric one-component sealants. They provide a not so strong connection of parts, but with their help it is very convenient to seal and seal various types of structural joints.

All agents, whether cyanoacrylate or any other polymeric, are one-component. This means that they are based on the same type of chemical. Polymerization takes place without the help of special hardeners. The process starts just moisture, which is always contained in the air. Of course, this greatly simplifies all the sealing work.

The described compositions are usually available in the following types of packaging:

- cyanoacrylate - small, “at once” tubes with a threaded plug;

- elastic polymer sealants, as a rule, are packaged in special tuba-cartridges for mounting guns;

- Sprays are spray packed.

The compositions used in glass works must meet the requirements of:

- good adhesion;

- strength;

- elasticity;

- durability;

- weather resistance;

- chemical neutrality.

Consider some types of sealing compounds.

Instead of the usual window putty, even for wooden window frames are increasingly used acrylic sealant. The product provides good adhesion with a variety of building materials, frost-resistant and versatile as a heater, moreover, quite elastic. After hardening, acrylic is wonderful plastered and painted. It does not emit dangerous toxins, and therefore completely harmless when working with him, and in operation. Plus, it has fire-fighting properties.

Most often, acrylic sealant is used when working with a facade for sealing joints between walls and window fittings.

But inside it is better not to use it, because after the final solidification, the material becomes porous.This leads to the fact that the seam can absorb all kinds of pollution from the environment, causing the appearance of the seam to deteriorate noticeably. If, however, this kind of chemistry still had to be applied in well-marked places, then it is desirable to prime and paint it.

Among the shortcomings, it can be noted that it gradually turns yellow, is not too resistant to water, its frost resistance is satisfactory.

In all types of glass works the most widely used silicone sealants. Such compositions are suitable for both domestic and outdoor use. They are elastic, perfectly attached to all materials. Despite some viscosity, the composition penetrates well into the gaps and joints. Not only is it very easy to use, this material is also inexpensive.

But silicone compounds are very poorly stained. In addition, most of their varieties during operation (before solidification) emit a sharp smell of vinegar, which imposes some restrictions on the rules of installation.

Perfectly tolerating temperature drops, aggressive effects (including oils), polyurethane sealant It is usually used for warming windows. It dries quickly, stains well.Elastic and hydrophobic polyurethane also tolerates moisture and UV exposure. Due to all the positive characteristics listed, these types of sealants are used in a wide variety of areas.

Unfortunately, polyurethane compounds contain corrosive substances, which is not always convenient for minor repairs or construction.

Polysulfide compounds served as the basis for the creation of such a class of sealing compounds as Teokolovye sealants. Independent of neither the temperature nor the level of moisture, such materials ensure reliable adhesion, seizure and stable solidification of the seam. In the production of outdoor work such substances can be considered the best choice. In rain, in snow, in cold weather - in any weather, ready-made compounds retain their excellent qualities.

Often called “liquid plastic,” polymeric sealants are based on MS polymers. Excellent fixation on plastics, rapid hardening and satisfactory strength make such compounds indispensable in the production of polymeric window frames, as a result of a solid construction with the rest of the elements.Disadvantages should not recognize too much mechanical strength and low elasticity of the composition. When connecting several layers of glass in a glass unit, as a rule, butyl sealant is used. Created on the basis of rubber-like substances, it has high elasticity and good adhesion both to glass and to metal.

The seam of a similar sealant well prevents water vapor and air from penetrating the glass unit. Elasticity and elasticity persist from -55 to +100 degrees. High UV resistance and harmlessness only emphasize the importance of such material in the glass industry. If you need a sealant is the most durable, the most resistant to the sun, water and aggressive fluids, then you can safely recommend rubber.

The highest strength and durability of such compounds are such that they seal the seams even in boats, which makes their use justified even in spite of the very high price.

How to choose?

For bulk sealing of the seams between the walls and window fittings, polymer foam is traditionally used. But in some cases more modern sealants may be more preferable.

If necessary, repair wooden windows (it does not matter whether they are old or new) is best suited acrylic. Due to its good water and vapor insulation properties, it can be perfectly used as a putty. Such compounds are not afraid of cold and stick well to most building materials.

Special sealants "liquid plastic" are indispensable as a secondary sealing of the edge of the glass in the process of assembling the window unit. Such processing creates an additional contour of strength and rigidity in the product, which allows the window to withstand any effects of temperature and humidity of the environment. These types are often used for structural glazing - for joining glass and metal during installation, for example, glass domes.

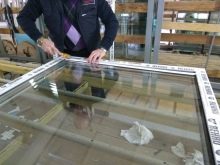

In the manufacture of glass units, careful attention is paid to ensuring that dirty air and water vapor cannot get into the product. Butyl compounds are absolutely indispensable for solving this problem. Such material is applied in a clean workshop, at a temperature of more than +100 degrees. After cooling, it becomes a reliable barrier between the atmosphere and interglass space.

The cheapest of the considered polyurethane sealant due to its exceptional resistance to external influences is widely used in the installation of facade glazing and sealing of construction joints.

Usage tips

When working with sealants, one should always thoroughly clean and degrease the contacting surfaces. In the case of repairing individual glass parts, it is easiest to use cyanoacrylate preparations. Algorithm of work:

- the composition with a thin layer to put on the crack as far as possible from both sides;

- in case of repair of parts, apply the substance to all contacting surfaces;

- squeeze parts for a few seconds;

- remove the film remaining on the seam after final curing (about half a day).

Thus, it is quite possible to fix a small glass or plastic thing without any special efforts with your own hands.

Before using the sealant for building installation, the window frames and openings must be well cleaned of dust and dirt. Despite the fact that the moisture itself contributes to the polymerization of the sealant, it also strongly interferes with the adhesion of materials, so that the surfaces should be allowed to dry well.Installation is better to produce when the weather is not colder +5, and it is highly undesirable to perform them in the heat more than +40 degrees.

First, the material is applied with a thin even layer along the joined surfaces and leveled along their entire length. The detected gaps are carefully filled with a thin layer of material. Drops of non-hardened composition can be carefully and quickly removed with a damp cloth. Those irregularities that can form after drying of the repair compound can be cut with a sharp knife.

Once the window frames are mounted, you can do the sealing of possible slots. For this you will also need:

- water in the basin;

- masking tape.

We glue the tape along the gap, which will protect the glass surfaces and slopes from contamination. Fill the gap carefully cleaned from dirt and dust.

If necessary, close the slot is most convenient to use a syringe (although with a certain dexterity a thin spatula is also applicable). In the case of a syringe, hold it at an acute angle and lead the seam so that the tip of the syringe smoothes the newly squeezed sealant. Wet finger can gently smooth out the irregularities of the resulting seam.

Finally, you can proceed to the final cleaning of the surface. Just right, a soft sponge, well moistened with water, is useful for this. Since the sealant is not quite frozen, this work should be carried out quickly, but very carefully.

Such work is best done in stages:

- we put material on not too big piece of a seam or a crack;

- level the sealant;

- quickly remove the formed surplus;

- we clean the working field with a sponge and only then proceed to the next section.

Such an approach to the execution of works will allow to exclude the preliminary freezing of the material and will relieve from the gross mistakes even the not very experienced master.

In the next video you will find the installation of glass on the sealant.