Neutral silicone sealants: types, properties and applications

Before the invention of the silicone sealant, it was difficult to achieve perfect sealing of the joints. The seams were filled with various putties, mastic, which over time deformed, covered with cracks and ceased to perform their protective functions.

With the advent of silicone sealant, many types of construction and repair work have been greatly simplified, and quality indicators have improved.

What is it like?

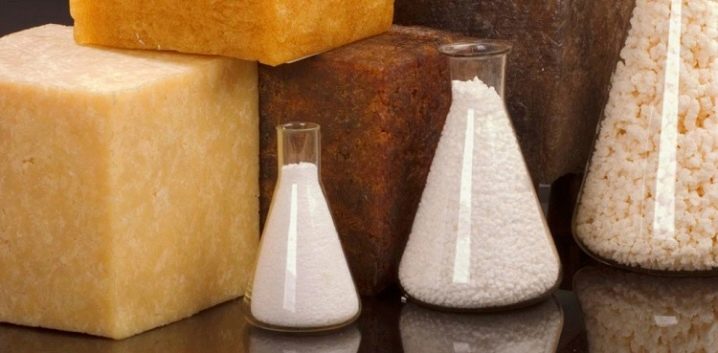

The composition of silicone resembles a viscous, soft and elastic structure, which, while freezing, seals up cracks, cracks and seams. Such solid components as sand, quartz and silicon are involved in the creation of the sealant, which gives strength and reliability of the surface being treated.

Single component silicone sealants are alkaline, acidic and neutral. Amines dominate in alkaline formulations. Acetic acid forms the basis of acid products. In neutral sealants, the content of alcohol or ketoxime allows working with any surfaces, which cannot be said about alkaline and acidic products, the components of which are incompatible with marble, cement, plaster, non-ferrous metals and some types of plastic.

The water-repellent properties of silicone do not allow to paint the sealant in the process of application. This product has a rich color palette, which makes it possible to immediately choose a composition that matches the tone, and colorless transparent sealants will suit any surfaces.

Advantages and disadvantages

Neutral Silicone Sealants have characteristics that highlight their merits:

- high degree of adhesion (adhesion) with almost all materials;

- elastic even in the frozen state (stretched), which makes it possible to apply a sealant on unstable areas;

- waterproof;

- fire resistant sealant transfers high temperature mode;

- endowed with a high degree of strength;

- durable;

- resistant to ultraviolet, climatic fluctuations, so silicone is used for both internal and external repair and construction works;

- when drying it is resistant to the environment of aggressive detergents;

- silicone does not affect mold and fungus;

- unlike acid-base types, neutral sealant is not aggressive to various surfaces, it contributes to its widespread use.

The disadvantages include some of its features.

- The impossibility of staining after application.

- Acid-alkaline species are not used in a wet environment, they are aggressive to certain materials, have insufficient adhesion to some polymers. Neutral silicone sealants do not have similar disadvantages, but their cost exceeds other adhesives.

Component composition

Special additives make a variety of silicone sealants, with their help, the product changes its characteristics:

- mechanical fillers (primer adhesion) provide adhesion of the sealant to the surface;

- extenders (vulcanizers) are responsible for viscosity;

- plasticizers give the material elasticity;

- rubber fillers are the basis;

- colored pigments are involved in the dyeing composition;

- fungicides are added to fight mold and fungus.

Choosing a sealant for the intended purpose, you should pay attention to the component composition of the product.

Kinds

Neutral silicone sealants are marketed by various manufacturers. They are classified by composition, purpose, color palette. The choice depends on the place and purpose of application. The purpose of the composition is indicated on the packaging. In most cases, sealants are divided into construction, automotive and special. They are available for indoor, outdoor, wet or dry premises.

To destination silicone sealants are of several types.

- Plumbing and sanitary. This type of product is equipped with antifungal additives, they repel water well, so they are used in rooms with high humidity: bathroom, pool, kitchen, bathroom. Sanitary silicone process joints of pipes, sanitary equipment. It has a high degree of adhesion, tolerates aggressive detergents, and withstands high temperature conditions.

- Automotive. Used to replace automotive gaskets.Silicone repels water, engine oil, but contact with gasoline is not recommended. Sealant withstands temperatures up to +300 degrees, durable and durable.

- Roofing. Sealant of this type has enhanced adhesion to brick, wood, bitumen, metals, plastics, ceramics and concrete. Indispensable in the treatment of tile joints, for sealing chimneys, skylights and other roofing work. It tolerates any climatic conditions.

- Construction. Neutral silicone sealant is used for all kinds of construction and repair work inside and outside. It has good adhesion with gypsum, metals, plastic and so on. Resistant to ultraviolet light, does not age and does not fade.

- For work with brick and stone. This product is designed to perform outdoor work, is well resistant to weather conditions, tolerates temperature fluctuations, includes fungicides, stopping the development of fungal formations. It has good adhesion to porous surfaces, is used for grouting, joining stone, plastic, glass.

- Aquarium. Adhesive sealant for glass does not contain harmful impurities, non-toxic.It has good adhesion to glass and other smooth surfaces. Used for bonding the walls of florariums, aquariums, terrariums, vases and glossy display cases.

This is not all types of work that uses silicone sealant. In everyday life there is always the use of wonder-glue that can "bind" any surface.

Overview of popular sealants

Neutral silicone sealants are produced by manufacturers in various countries. Many types of products of excellent quality have proven themselves in the construction market.

As examples, we give some of them.

- Loctite 5699 - refers to gray neutral sealants. It is used for automotive gaskets used in engines. Does not emit odor, does not corrode, does not affect the oxygen sensor.

- "Siloterm EP-71" - fireproof, fireproof sealant. It is used to work with cable products, for grouting construction joints, sealing windows and other things. Suitable for electrical insulation coatings, waterproof, frost-resistant, anti-corrosion, explosion-proof.

- Krass silicone neutral - Polish glue of white and transparent color, has excellent adhesion with most building materials, withstands extensive deformation of joints.It is used in construction, shipbuilding, tin work and in car repairs.

- American sealant Abro 999 silicone black. Designed to repair gaskets in Japanese cars. Well applicable to work with European and American cars.

Mode of application

For high-quality glue adhesion with the material, the surface should be prepared for work. It is necessary to remove dust and various contaminants, degrease with a special composition seams, cracks and other places intended for grouting. Sealant produced in tubes of 300 or 600 ml. For work, you will need a plunger construction pistol, in which a tube is inserted with a cut-off top and a dispenser.

Prepared dried joints or seams are filled with silicone, the excess should be removed with a damp cloth. If the adhesive mass is still frozen in the wrong place, it can be removed with a solvent. The appearance of the film occurs fairly quickly, but the full drying of the working surface occurs in a day. Drying time depends on the thickness of the applied layer of silicone.

Neutral silicone sealant is a durable, reliable and durable material, without which in everyday life, construction and production today it is difficult to do.

In the next video you will find instructions on the use of neutral silicone sealant Penosil General Silicone.