Drawings of fireplaces from bricks

Choosing the size and shape of the fireplace

Fireplaces made of bricks are well suited for heating large rooms in country houses without central heating. These can be buildings made of wood, gas silicate blocks, logs or other material. With good thermal insulation of walls there is an opportunity to build an open stove that can cope with heating of any area. The virtues of a brick fireplace in high Efficiency from work - it reaches 80%, strength, long-term retention of heat, durability and ease of maintenance and cleaning.

The choice of the size and shape of a brick fireplace depends on the following conditions:

- the area of the heated room;

- location in the room;

- selected type of structure;

- features of the building - the foundation, flooring, wall insulation, the location of the chimney pipe;

- functionality of the future fireplace.

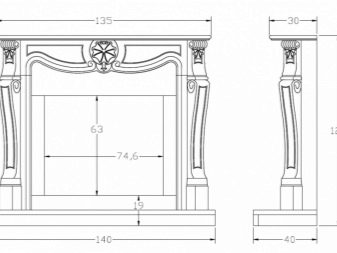

The area of the furnace hole for a brick fireplace should be about 100 times smaller than the area of the heated room. The height and width of the firebox are selected in a ratio of 1.5 to 1, the depth is 1.5-2 times less than the width, the cross-sectional area of the chimney is 10-15 times smaller than the area of the firebox. For example, based on these parameters, for a room in 24 square meters. m. you can make a drawing of the fireplace with such dimensions:

- firebox area - 0,24 square meters. m .;

- firebox width - 40 cm;

- its height is 60 cm;

- depth - 20 cm;

- chimney cross section - 0.024 square meters. or 240 square meters. cm.

By location in the room there are fireplaces wall, corner and island.

- The first option will require the most material and the solution, but as much as possible will cover the room with heat, and around it you can sit in a large company. The drawing of such a fireplace is often symmetrical, the facade is U-shaped, in most cases brick laying is required, covering the chimney up to the ceiling.

- Corner fireplace it can be compact, requires a small number of bricks, lining occurs only on one side, the role of the other two is performed by the walls of the room. Despite its small size, this option can effectively heat a room of 20-30 square meters. m. in a short time.

See in the video how to make a corner fireplace with your own hands.

- Island Fireplaces They are usually located in the center of the room, not adjacent to the internal ceilings. They have the form of a pool with low sides, inside which put firewood for kindling. To remove the smoke over such structures have a suspended hood. Such projects require a minimum of building materials, and their drawings are extremely simple, most often in the profile projection they represent a square or rectangle. Although some are installing in their country house and more complex forms of island fireplaces are round-shaped, multi-level, with a table top.

- Separate option are outdoor fireplace for barbecue, barbeque, built-in garden pavilion. Their models are more diverse, especially when the area of the site allows the construction of a large building with many elements. They necessarily require a foundation on a concrete base in order not to get bogged down over time and not to float in the yard ground. Before starting construction work for the outdoor fireplace with a barbecue, you should create detailed drawings with the ordering of bricks and plans of various projections.

If the outdoor fireplace is made in the street with a gazebo, the walls or roofs are usually made of wood, plastic, metal profiles, and other lightweight materials. In addition to the furnace itself, the brick columns may be bearing columns, the platform in front of the firebox to prevent from fire.

Species

A brick fireplace for heating a room consists of 4 main parts:

- a portal containing a brick facade;

- firebox - a place where firewood is placed;

- smoke box, which serves to smooth the transition of smoke into the chimney;

- chimney that brings smoke to the street.

Internal fireplaces are open and closed. The first option does not require that a cast-iron insert be built into the portal, which protects the walls from open fire. But the inner walls of the furnace at the same time must be made of refractory bricks. This is a special grade of building materials, which is obtained by pressing and firing chamotte mass or quartz.

- The advantages of open fires in the beauty of natural fire in the interior of the room and the ease of installation of the portal without a bulky cast-iron wardrobe, which has a considerable price. But with the option open, there is the likelihood of sparks entering the room,therefore, the area in front of the fireplace should have a fireproof coating. Sometimes it is made of the same brick as the fireplace facade.

- If the firebox of the fireplace is made of cast iron, then it can be both open and closed. The inner surface of the niche in this case can be constructed from the usual non-refractory bricks - protects the metal from the flame. Open fireboxes are safer, they prevent sparks from entering the room, the device of their door can be a side or top opening. Dampers for home fireplaces are made of tempered fireproof glass - burning firewood and flames are visible through it.

So that the transparent material is not covered with soot, it is covered with a special smoke-repellent layer.

- Wall and corner fireplace erected with a chimney. It’s best to hide its metal pipe with decorative brick trim; besides beauty, it provides additional insulation and durability of the smoke exhaust system. For the masonry chimney, as well as for the portal, you must create drawings with ordering.

- Island fireplace most often it does not have a chimney made of bricks, ready-made metal hoods are sold for it, which are suspended from the ceiling.

Calculations and drawings

Calculations of the size and layout of the future fireplace should be prepared in more detail in advance, even before purchasing the necessary materials. From the visual drawing, it is always clear what quantity of ordinary, refractory and facing bricks should be purchased. It is better to buy a little more than you need in the finished project, with the expectation of a marriage at work or small amendments in construction.

Next, you need to calculate the consumption of cement for masonry work. Depending on the type of material, there are different calculation methods. But you can take the most common type of dry cement mixture for kiln works - M200. It is mixed with sand in a ratio of 1: 3. Further, this dry mixture is diluted with water and thoroughly mixed to a thick homogeneous mass. For laying 1 cu. m. brick need about 0.3 cu. m. of such cement-based mortar M200. The volume of the chimney facade and lining of the chimney can be calculated from the dimensions of the drawing. A simpler way to calculate is to multiply the volume of one brick by the number of bricks, this will give an approximately accurate result.

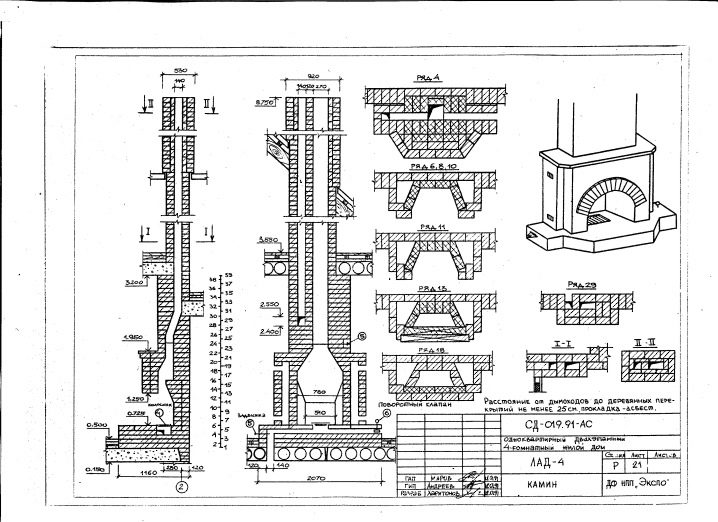

A drawing of a finished fireplace usually consists of a horizontal and frontal projection. These two types give a detailed idea of the height, width and thickness of the portal with the chimney, the number of bricks for each row, and the way they are bonded. For firebox, especially with a hole in the form of an arch or a trapezoid and inclined inner walls, you can create separate visual drawings with different projections. The most important thing is for the master to understand how the smoke box is located inside the furnace, how the chimney is fixed, and at what angle in the niche the walls are inclined.

Operating procedure

After creating the drawings of the fireplace with the size and ordering of bricks and the acquisition of the necessary building materials it is necessary to prepare working tools. Their list is as follows:

- capacity for mixing the solution, optimally - with a volume of not less than 50 liters, if there is an electric mixer, then this is even better;

- sieve and capacity for sifting sand, if it is with large impurities;

- mortar trowel;

- building level length of 1 - 2 m;

- roulette, ruler, square;

- pencil or marker;

- hammer.

For laying you may need additional items, for example, a knife, a Bulgarian, a hacksaw, a rag, a container with water - it all depends on the nature of the work.

Before you start it is most convenient and functionally to organize a workplace, to bring extenders with sockets, lighting, to protect interior details from possible dirt.

You can easily install a brick fireplace with your own hands according to the drawings, even without the experience of such construction work, if create a preliminary step by step plan.

- Installation work begins with the installation of the foundation.. It can be tape from concrete, from blocks or bricks. If the foundation is filler, then the formwork of wooden panels is pre-built, a liquid concrete solution is poured into it. Laying of the facade of the fireplace at the same time begins only after complete drying and shrinkage of the foundation.

- On the ready base there is a decent layout of bricks. in accordance with the developed drawings. The ordering scheme contains all the stages of construction with the arrangement of fragments. Laying along the rows should be done very carefully, observing smooth seams, a bunch of bricks and a horizontal level. After the formation of each row, it is necessary to make an additional check of the level and, if necessary, an adjustment, until the solution has dried.

- After the construction of the fireplace portal should take up the installation of the chimney. The metal exhaust pipe is attached to a horizontal wall, additionally insulated. Then it is surrounded by a brick wall according to the existing drawing.

- After the brick base of the portal and the chimney of the fireplace is ready, you can proceed to decorating, decorating the countertops, gratings, shelves, dampers and other elements.

In no case can the built fireplace be immediately exploited. From the time of construction to full firing should take at least 2-4 weeks. Before that, to dry the stove and chimney, they organize a partial firebox with a small amount of firewood. Begin with 2 kg of dry logs, every 2 days increase the weight per kilogram.