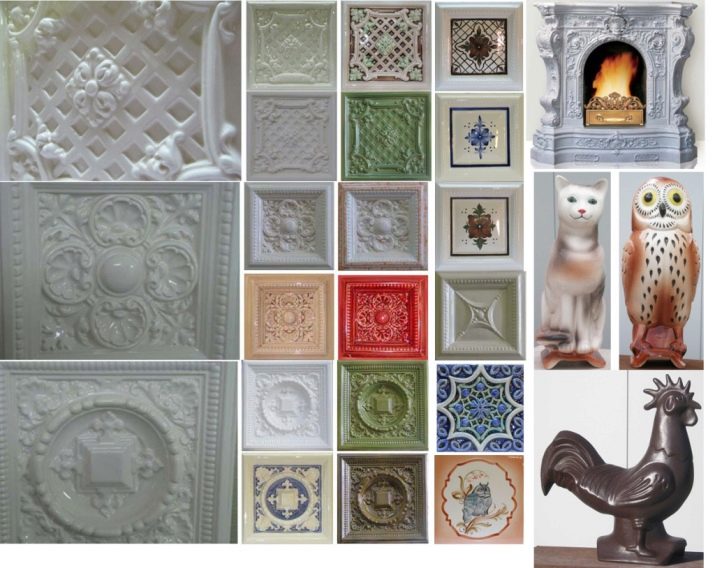

Fireplace tiles

The tile is a ceramic tile which is used for finishing of an external surface of furnaces, fireplaces, buildings and so on. It is used in order to increase the attractiveness of structures, as well as to increase their resistance to the negative effects of the environment.

Fireplaces decorated with tiled tiles are safer than those that do not have a similar finish. Good thermal insulation properties of ceramics contribute to the uniform distribution of heat through the air, and if the heat inside the fireplace hearth accumulates to the maximum, only a small part of it gets out.

It is remarkable that the chimney tile is not suitable for cutting.

It can be placed on the surface of the fireplace only as a whole, otherwise the unique insulating properties of the material are lost. In view of this, a chimney tile can be different and differ not only in appearance, but also in form, as well as other indicators.

Kinds

To tile in the process of laying did not have to be customized in size and shape, it is produced in accordance with the parameters of the individual fireplace elements:

- Flat - designed for finishing the smooth surfaces of the fireplace.

- Corner - used when facing the corner elements of the structure.

- The basement is mounted on the lower rows under the firebox, and also placed under the portal.

- Shaped - put on the protruding corners of the fireplace and has more decorative value.

Tiles and surface texture vary: they can be smooth and embossed, as well as glossy and matte. In the decorative plan there are also differences: the tile can be monophonic, that is, not have any pattern, as well as with a pattern.

The theme of the pattern on the tile directly depends on the country of origin. Russian sets of tiles are the most colorful and display floral motifs. Bavaria, on the contrary, offers discreet colors and is decorated with geometric patterns. Dutch tiles can be recognized by the blue-white shade, and Spanish - by patterns in the oriental style.

Fireplace dimensions are clearly regulated by GOST.The thickness of the product varies from 45 to 50 mm, and the width and length correspond to 200x200, 220x220 and 205x130 mm.

Special features

The main distinctive feature of the tile is the presence of a rump - protruding sides from the back of the product. They are intended to connect the tiles with each other in the process of laying and may be with an inclined cut or voids inside.

Rumps are mounted on special pins, so even at the stage of the construction of the fireplace should take care of their installation. If the fixtures for tiled tiles will not be provided, you will have to give preference to another housing material.

The process of making tile is unique, complex and long. It covers several stages:

- Special cleansing clay is first kneaded for a long time manually, and then left to warm for several weeks.

- After that, it is placed in a mold and gradually dried. The stage is rather difficult, as the clay should be dried in the most dry conditions and without temperature drops.

- After complete drying of the clay, it is burned and coated with glaze. In the subsequent drawing and clay, which has already become ceramics, is applied, the final stage of firing takes place, which lasts 24 hours.

The outer part of the product under the influence of high temperatures can change the shade, so it is advised to sort the finished tile before laying.

Since the production of tile tiles for stoves is provided for manual work, its cost is always quite high. In an effort to save money, many prefer to create tile tiles at home.

Do it yourself

In order to make tiles yourself, it will take a lot of effort. The whole manufacturing process can be combined in several stages:

- Preparation basics. Small pieces of clay should first be dried under the hot sun, and then sieved through a sieve to remove debris. The resulting powdered mass must be filled with water, stirred, cleaned once more and left in the sun again to evaporate moisture. At this stage, the clay will need to be constantly mixed, and when it acquires the consistency of thick dough, it will be possible to proceed to the next stage.

- Creating a blank. First, the clay is flattened into a tortilla, and then leveled with a knife, giving the desired look. A pattern is applied to the surface of the model using wire or stacks.Next, the workpiece is placed in the formwork and filled with plaster. After 15 minutes, the clay is separated from the gypsum and proceed to the next stage.

- Molding. In order to form a clay tile, you will need a special plaster mold. In her soft clay billet is placed with the onslaught. On top of the workpiece is lined with four bars of clay on each side. They are drilled holes for mounting.

- Polishing and roasting. After removing from the mold the hardened clay, it is necessary to polish its surface with a pebble and leave it for another few days until fully cured. Next, the tile for 3 - 4 hours is placed in a special kiln. In the firebox, a constant temperature is maintained equal to 900 C. In a closed, but not heated furnace, the tile is left for a day until it cools completely.

- Painting and glazing. Painted tile oil paints, and glazed with a special mixture made from starch paste and crushed glass. It should be noted that both after painting and after glazing, the tile must pass through the stage of re-firing.

In this process, the manufacture of tile can be considered complete.Such a finishing material is suitable even for facing round fireplaces, and their shape is really difficult in the finishing plan.

Tiled fireplace in the interior

Fireplaces lined with tiled tiles are not just beautiful. They acquire unique external characteristics that you want to admire. Such fireplaces create an atmosphere of comfort and tranquility in the house, allow you to relax, enjoy the warmth of the hearth and get aesthetic pleasure. However, much depends on the correct location of such a fireplace in the interior.

In houses with a small area or apartments, fireplaces are usually installed in the corner. A place ideal in terms of space saving, but with such an installation, only the front part of the fireplace is accessible to the gaze. This means that it is possible to cover only a section of the portal above the firebox with patterned tiled tiles, and to revet the remaining elements with plain patterns of tiles.

For a country house with a large area designed Swiss fireplaces. They are installed in the center, so hand-painted tiles can impose a fireplace around the perimeter.Even the use of mosaic elements is permissible, when individual ceramic tiles form a pattern.

Special attention should be paid to the style in which the interior is decorated:

- The laconicism of the classic style is best emphasized by fireplaces decorated with German tiles, as well as tiles without a pattern.

- The true freedom of Art Nouveau is perfectly combined with the Dutch-style tile fireplaces.

- The fireplace, lined with Russian and Yaroslavl tiled tiles, will ideally fit into the good old country style.

- The minimalism of the English style is better not to break the flashy interior. A pastel tile fireplace is the best choice for this atmosphere.

- For the interior, decorated in Greek style, suitable fireplaces, decorated with tiles with floral motifs.

Based on the above, it can be understood that ceramic finishing materials are one of the best of their kind. The main secret of their popularity is that they are environmentally friendly, safe, durable and extremely beautiful. The high cost and complexity of manufacturing (in the case of tiles) - the only drawback.