Features of glue for drywall

When carrying out repairs, many prefer to use drywall, which helps to hide all surface irregularities. However, the installation of sheets of this material carries additional difficulties and costs. Special glue solves this problem.

Special features

Before you use glue to install drywall, you need to prepare the surface. To do this, it should be cleaned of dust and dirt, primed in two layers, which will enhance the adhesion of the surface with the finishing material and strengthen it.

The primer is carried out in several stages:

- the first layer is applied evenly on the surface and left to dry;

- The second layer is applied after 24 hours with undiluted mixture and aged for one day.

Glue for drywall has some advantages over other methods of fastening material:

- Quick installation. The use of adhesive composition will reduce the time spent on the installation of gypsum boards.

- Fast hardening - within 1–1.5 hours. At that time, while glue will be applied to the entire surface, it will be possible to proceed to the putty.

- Simple use. The adhesive is easy to prepare and apply due to its high plasticity. Equally important is that there is no need to pre-level the surface.

- Efficiency. Compared with other methods of drywall fasteners, the use of glue will reduce costs several times. In addition, the area of the room will decrease by a maximum of 20 mm on each side, while at the same time installing the plates on the frame will reduce the area by 40 mm.

These facts justify why it is better to choose a glue for drywall, and not another method of fastening.

Kinds

There are 4 types of adhesive for drywall:

- mounting;

- mastic on a plaster basis;

- specialized adhesive composition;

- polyurethane foam.

Construction adhesive requires compliance with a special cooking technology, which is indicated on the packaging. This type of glue is applied to the prepared surface with a spatula in a circular motion. During the installation of drywall boards, it is necessary to monitor the uniformity. For these purposes it is best to use the level at which the plates are installed. You can change the position of the set sheet in the next 10 minutes.

Part mastic on plaster basis includes adhesive component and lime. The glue is dissolved in water and left for 14 hours to swell the granules. Then add lime, diluted with liquid. Gypsum mastic has good adhesion. Grasping occurs within 50 minutes.

Specialized adhesive sold in bottles of 750 ml. It is applied in the ratio of 1 cylinder to 15 square meters. This glue also has good adhesion, but it can only be used at the same height around the perimeter of the room.

Bonding drywall with foam includes:

- the presence of about 10 holes around the perimeter of the panel;

- foam stickers at a distance of 10 cm from the holes;

- installation of sheets of gypsum boards on the wall and strengthening screws;

- Filling foam in the holes.

Before finishing the wall with plasterboard, you need to assess the overall situation.

When it comes to surfaces with defects, the use of putty will help save the situation. However, this can only be done by an experienced specialist. The process of leveling the walls is quite a long and painstaking work. Tiled plasterboard can level depressions and bumps.

Scope of application

Let us see what compositions are used in various cases when installing the gypsum board.

- Gypsum mastic is used for gluing plasterboard to the brick surface. The composition based on gypsum is economical to use - about 5 kg of glue will be enough for 1 square meter.

- Not bad copes with the same task assembly foam, characterized by low price. One 750 ml bottle can glue 10 square meters of surface. Foam is used by most people to insulate their homes. However, there is one drawback of this composition: the expanding ability, which implies the subsequent fastening of the sheets with the help of dowels and self-tapping screws.And this is an additional cost and effort.

- The adhesive is used for decorative plaster, making the surface original and interesting.

- Adhesives based on gypsum or polyurethane can be used to attach sheets of plasterboard to a concrete surface. In addition to plaster mastic, for the finishing of concrete can also be used assembly foam, cement compositions and putty.

- Specialized adhesive is used for gluing drywall to polystyrene foam.

- A special adhesive for tiles is a silicone compound for gluing tiles on a plasterboard. This composition is not afraid of high humidity and temperature changes, which allows its use in bathrooms. Sealant is also used to fill the joints between the tiles; transparent or colored glue is suitable for this.

- Pasting of plinth and drywall. To glue these surfaces, suitable silicone sealant or universal glue.

Consumption

As a rule, the consumption of adhesive for drywall per 1 m2 is indicated on the packaging. However, this value is affected by the flatness of the surface:

- for gluing to a flat surface the consumption per 1 m2 is 1⁄2 kg of the mixture;

- for mounting a wall with visible defects - up to 5 kg;

- when mounted on a wall with tubercles up to 2 cm - up to 6 kg;

- up to 2 kg of the mixture per 1 square meter is used for gluing the tiled partitions.

Manufacturers and reviews

Glue for drywall is selected based on the type of room, the base of the surface and the experience of specialists.

German manufacturer Knauf ranks first in the building materials market. Given the good reputation of the company and the quality of adhesives, many prefer to repair the manufacturer Knauf. The company also produces drywall sheets, but its adhesive mixtures are also suitable for other manufacturers of gypsum plasterboards.

Many buyers of Knauf products are satisfied with their purchase. After all, thanks to a short shelf life, the customer always gets a fresh, high-quality product. The manufacturer has a warranty on their products with proper storage and use. But he does not vouch for products whose use rules and shelf life have been violated.

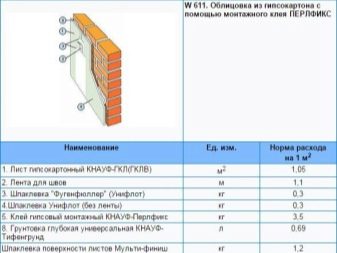

Perlfix blends are produced under the brand name Knauf. This composition is considered ideal for drywall.

Perlfix has the following specifications:

- use in temperature limits from +5 to +30 degrees;

- optimum thickness for fixing panels - 20 mm;

- resistance to high humidity, which allows the use of the composition in the bathroom, in the kitchen and on the balcony;

- after preparation of a solution of the corresponding consistence it is necessary to put it within 30 minutes;

- surface hardening occurs after 7 days at room temperature;

- shelf life of a closed package - 6 months;

- consumption of 5 kg per square meter;

- to apply the composition, it is enough to dilute the dry mixture with water;

- safety for human health.

Customer reviews of the mixture Perlfix suggest that glue is the most common tool for GCR, has a low cost.

Domestic manufacturer Volma exists in the market of building and finishing materials since the middle of the last century. The range of products of the company are: plaster, putty, installation mixtures, drywall. The manufacturer produces environmentally friendly products, thus paying special attention to environmental protection. Every year, Volma modernizes its production technology and improves the quality of its products.

Gypsum glue "Volma" for mounting HL has the following characteristics:

- consumption - 2 kg per 1 m2;

- hardening - 24 hours;

- packaging - bags of 5, 15 and 30 kg.

Customer reviews about Volma products are very positive, which allows us to state that the products of a domestic company are not lagging behind imported products, and the reasonable price allows you to buy adhesives for almost any buyer.

Tips and tricks

Use the advice of experts, and the process of gluing drywall runs quickly and smoothly.

How to prepare the glue for gypsum?

Glue for drywall is prepared quite easily, for this you need a mixer with a whisk or a nozzle drill. The use of the latter is not always successful - a good solution is rarely obtained.

There is one important rule that must be followed when preparing any solutions, including the adhesive composition for drywall: do not pour water into powder, and powder is poured into a liquid. Violation of this rule will lead to the deterioration of the solution - it turns out with lumps.

It is necessary to take a container for the resulting solution, pour water into a third of the volume, pour dry powder until a small pile of powder appears.Then you can stir the mixture using the selected tool to obtain a homogeneous composition. The density can be adjusted by adding water or by filling up with dry powder.

One important point should be taken into account. It is possible to thicken or dilute the solution in the next 5 minutes, otherwise the glue will become non-plastic. With proper glue preparation, you can use the composition within 40 minutes.

A few tips to help when installing drywall boards:

- Glue is applied in four rows on the surface: the first two rows are at the edges, the other two are centered. The distance between them should be the same - about 40 cm.

- To align the sheets, you can use a pair of metal profiles. The level will also be useful.

- The edges of the glued sheets are lined with glue.

How to glue drywall?

Installation of drywall is not particularly difficult, even for inexperienced people. After surface preparation, an adhesive is applied to the drywall, pressed against the wall and leveled along the marked lines.

After that, you should press down the sheet a little more so that the glue spreads over the surface and the drywall is tight.Finally, drywall putty. Such a technique will help save some floor space.

Preparation of the base is as follows. A primer is needed for the surface, and the construction of gates for wires. If the base is brick - then special attention should be paid to the elimination of roughness and irregularities. For these purposes, putty or drywall strips are used.

Foam blocks, gas blocks do not create similar problems, but if there are some irregularities, then apply gypsum solutions.

How to fix the drywall adhesive solution?

Mainly on what kind of glue was originally chosen for repair and for which surface, the result of the work depends. For example, for uneven surfaces need more glue than for even. The thickness of the layer of the solution eliminates the roughness of the base.

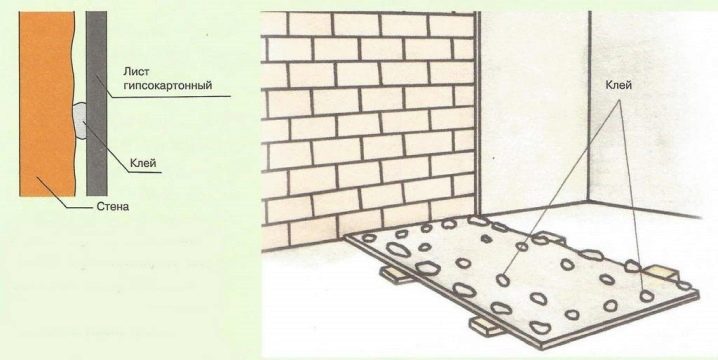

For bases without differences (concrete, plastered walls) the process of gluing plasterboard looks like this:

- make cable plugs and holes for sockets;

- a primer mixture is applied to a clean surface; in the case when the glue does not stick, the quartz filler will help solve the problem;

- drywall sheets are being drilled for electrical equipment;

- glue is applied with a spatula, the excess is removed;

- the slab is placed face down;

- before the sticker, it is slightly lifted and the cables are directed into the holes;

- drywall is applied and more tightly attached to the wall with a light hand tapping.

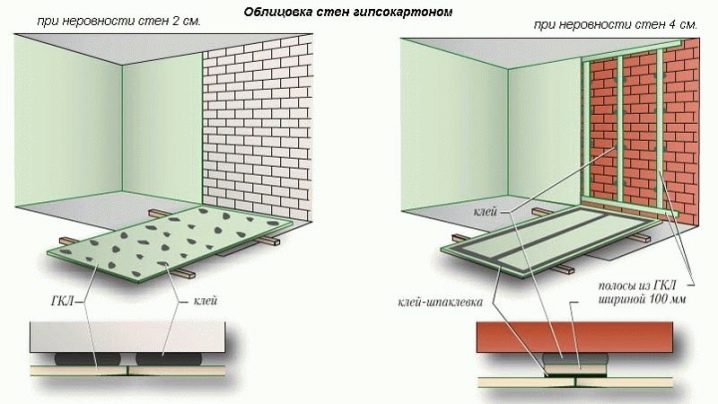

For surfaces with irregularities up to 20 mm, plasterboard is glued differently., but preparation, primer is not different from the previous version.

- Prepare glue a little more than for a flat surface, put on GCR not with a spatula, but in separate piles. Thus, irregularities are eliminated and a reliable fixation of the sheet on the surface will be ensured.

- Glued from the beginning of the output cables and clamping sheet GCR, which is hooked to the base. It is better to carry out repairs in the company of people, so that one holds the material and helps to press it.

- At the end, check the plane to determine where to press the sheet. If there are such areas, they are compiled to obtain the desired results.

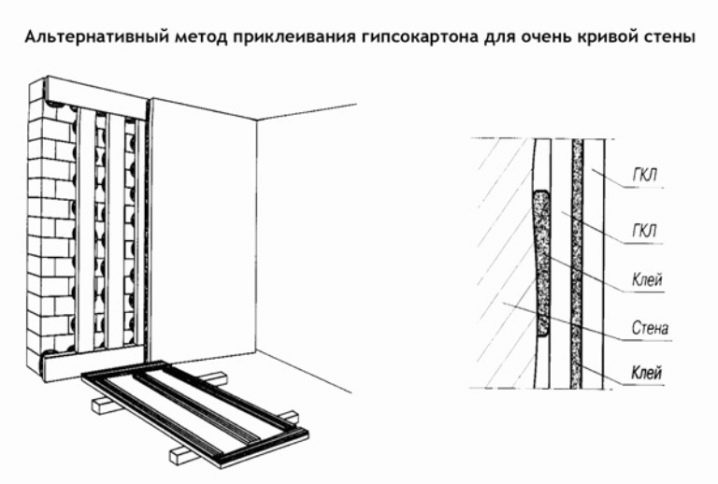

For a surface with large differences (over 20 mm), the step-by-step instruction looks like this:

- get rid of fragile areas of plaster;

- ground surface;

- beacons are made - strips of 10 cm wide are cut out of the sheet, which are placed along the perimeter of the base and vertically, then they are fixed with an adhesive solution;

- GKL main plates are installed on the beacons with the help of glue, which is applied along the line, after it rises and presses against the beacons, and if all the rules are followed, the installation will not be difficult;

- joints are treated with putty or glue;

- after drying should be primed again and putty.

Is it possible to glue the ceiling with plasterboard?

When finishing the ceiling, many prefer this material. But in this case mainly thin sheets are used. And also much depends on quality of glue.

Experts identify several types of mounting GCR. In order to ensure reliability, stops are often used, which put pressure on the sheet and abut the floor, thereby preventing the drywall from coming off until the glue dries. Wooden bars can be used as them. Some argue that to facilitate the work you can paste over the sheets, cutting into pieces, and not entirely.

On how to glue drywall on the wall, see below.