Hot melt glue: what is it and how to work with it?

For the construction and repair of new products are produced annually, which have innovative qualities and improved characteristics. However, there are those materials that are time-tested and do not give up their positions. Among them - hot melt glue popular with builders.

Special features

Hot melt glue is a special adhesive substance that can repeatedly melt and harden, thereby ensuring the connection of parts together. It is made of polymers based on ethylene vinyl acetate, polyester, synthetic rubber and polyamide. The raw material from which glue is made gives it some unique properties. So, polyolefin glue is able to glue the most complex and different in texture materials, and synthetic rubber in the composition allows you to save the adhesive,applied to the surface in a sticky state for an unlimited amount of time.

However, all hot melts have common features, including:

- fast and durable connection of various materials without serious physical and financial costs;

- minimum gluing time due to the fact that the glued product does not need to be further dried;

- non-toxic composition and its safety for the environment and humans;

- good frost resistance, glue does not crumble after repeated cycles of defrosting / freezing;

- easy storage and application;

- heat resistance - glue does not support burning;

- does not shrink;

- The compositions fit well on any surface, including rough and uneven.

But besides the good technical characteristics, hot melts also have a number of drawbacks. So, to work with this composition, you must purchase additional equipment, for example, a glue gun. Also, this material is easy to burn, so you should take seriously the protection of hands while working with him.

Kinds

Hot melt adhesives are divided into several types depending on the material from which they are made.

The following types of adhesives are available on the market.

- Polyolefin (PO marking). This adhesive is particularly resistant to aggressive chemicals as well as temperature changes. The composition is used in the automotive industry, the production of electrical equipment, as well as in the packaging of various products. They are fastened to wood, PVC, foil, leather, as well as materials of synthetic and natural origin, which emit resin.

- Ethylene vinyl acetate (EVA labeling). One of the most popular and hot melt adhesives on the market of building materials. It is used for plastic, thin metal, soft wood, cardboard, leather and ceramics.

- Alpha-polyolefin (labeled APAO). These adhesives are able to maintain stickiness up to 10 minutes depending on the manufacturer. Suitable for combining complex materials that react poorly to high temperatures, and for materials with a large bonding area.

- Rubber (marking PSA). Made from synthetic analogues of natural rubber. The longest of all types of glue retain stickiness. Used for complex surfaceshowever, there are restrictions - heating above 80 degrees is prohibited.

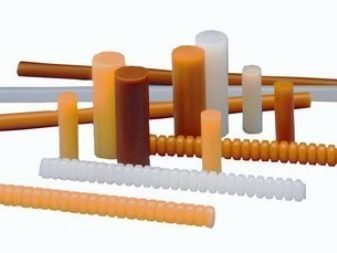

In appearance, hot melts can be represented in the form:

- rods;

- pillows;

- granules;

- blocks.

Hot melt glue is also available in the form of mastic, which is intended for gluing cellular concrete, GWP and cork slabs.

Brand Overview

Most manufacturers of modern building materials produce their hot-melt polymeric compositions. The most popular are the glues of the brands Dragon, Poxipol and Volma.

Dragon - Polish manufacturer of chemicals for the construction industry. In the assortment you can find not only hot-melt compounds, but also paints, solvents, assembly foam, primers and much more.

Dragon hot melt glue is used for the manufacture of building structures, bonding plastic, vinyl, leather, metal, fabric, ceramics. It has a fast setting period (about 20 seconds), is resistant to adverse natural factors, can be used both inside and outside the room. Glue does not pass water and can be used in rooms with high rates of humidity.

Poxipol - glue of argentinian manufacturerwhich allows to solve many problems not only in construction, but also in repair of premises and household items. It is very popular and has earned praise from professionals due to its convenience and wide range of applications.

Volma - Russian manufacturer, which is a wide range of building materials, including universal adhesives and pencils for cellular concrete and GWP.

How to choose?

At first glance, hot melt adhesives are universal. However, to be sure about the high quality of the work, it is necessary to take into account some peculiarities.

When choosing a glue, pay attention to the following points:

- white almost transparent rod can be used to connect any materials, it is universal;

- colored rods are intended for gluing colored ceramics, for exterior work on the facade;

- White frosted rods can be used for white parts from different materials, and for glass, for example, for the repair of a glass table;

- yellow shade glue is used to join paper, cardboard and wooden parts;

- dark gray and black rods are designed to seal the seams and insulate the electrical conductors.

In addition, you should carefully examine the composition on the package and follow the manufacturer's recommendations. So, some materials are not suitable for exterior work, and some can be carried out installation of artificial stone on the facades of buildings.

Heat-resistant pressure-sensitive adhesive is used for decorating furnaces. Universal rods can be installed flooring, MDF panels, clinker steps and salt bricks.

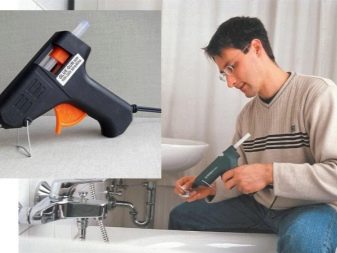

Related tools

Depending on the release form of the adhesive to work with it The following tool may be required:

- glue gun;

- batcher applicator;

- special glue machine that works autonomously (without electricity);

- glue roller;

- notched trowel;

- construction glue gun with a foot pedal.

The choice of tool will also be determined by the materials with which it is necessary to work and in what quantities. For gluing wall panels, laminate to the floor or other massive construction work, it makes sense to use professional equipment that can produce more glue per minute than, for example, a household glue gun.

Recommendations for use

When working with hot melt glue, great attention should be paid to safety and personal protective equipment. The fact is that the heated composition can get on the skin and cause a serious burn. Therefore, all work should be carried out in thick rubber gloves.

In order to avoid glue stains, it is necessary to put a rubber mat under the equipment in which the composition is melted.

Most hot melts can be put on the surface at a temperature of 5 to 30 degrees. In this case, the composition is heat-resistant and frost-resistant, that is, it will withstand more than one cycle of defrosting and freezing.

Progress with the hot melt is as follows.

- The tool selected for applying the composition is inserted (for the rod) or filled with hot melt adhesive (for the granules).

- After that, the operating temperature is regulated. Some formulations begin to melt at 90 degrees, but to ensure continuity of work and high speed, the temperature should be in the range of 170-200 degrees.

- The heating time of the equipment can vary within 5-8 minutes. It is not recommended to use the tool until it has reached the set temperature, as this can lead to breakage.

- Adjust the glue output if possible. Professional tools also control the stroke, which allows you to change the amount of consumable glue.

- The composition is applied to the bonded surface in the required quantity. The supply of glue is regulated by pressing force.

- After applying the surface pressed against each other.

It is important to monitor the amount of glue remaining to add a new batch in time.

Useful tips from the pros

To work with hot melt it was easier, you need to know some subtleties.

Professional builders make the following recommendations.

- You need to be serious about choosing the type of glue. It is important that it is intended specifically for the bonded surface.

- In no case do not need to mix adhesives of different composition and manufacturer. Different chemical compositions may affect the final quality of the gluing.

- Viscous compounds are applied with a spatula or roller, and more liquid ones - with a gun.

- Glue can be applied in any way depending on the size of the surface and other characteristics, but most often it is applied in a straight line or sinusoid.

- If the hot melt glue is on a clean surface, it can be removed with acetone or 97% ethanol.Oil formulations are not suitable for this purpose. Also, the surface can be ironed with a hot iron by placing a piece of white cotton fabric.

Hot-melt glue is a universal remedy that is used not only in everyday life, but also in construction and repair. Thanks to a simple application algorithm and a minimum of the necessary tools and skills, even a person far from construction will cope with this task.

In the next video, 15 useful life hacks with hot melt are waiting for you.