What are the sizes of PVC panels?

To date, high demand for interior and exterior decoration of the premises is used by PVC panels, the dimensions of which are of great importance when choosing this building material. This multifunctional product is used in any premises, creating a unique image in the interior.

Standard parameters

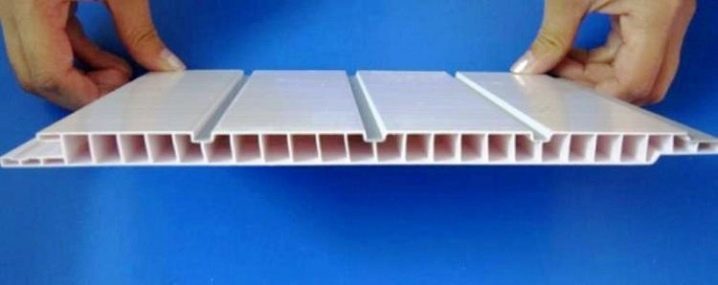

PVC panels are two polyvinyl chloride plates, interconnected by stiffeners. One of the faces is the front side, decorated by a specialized technology, that is, has a decor. PVC panels perform not only a decorative function when you make a room, they also create additional insulation in the house. TO

In addition, plastic products protect the ceiling surface from the effects of aggressive environment, and also hide some of the drawbacks of the ceiling (irregularities, leaks).

Manufacturers produce not only PVC panels for ceiling surfaces, but also for vertical (wall). Basically, when choosing a finishing product made of polyvinyl chloride, you should pay attention to the standard dimensions of the slats. But manufacturers produce decorative panels not only according to the standard, so it is possible to order a panel of any size.

The length of the slats can be different - 270 cm, 3 m, 395 cm and 1.2 meters. Thanks to this diversity, it is possible to mount on the necessary surface, which has a large area. The most sought after panels are 595 cm long, because they can be used as a finishing material for small and large rooms.

The width of the building material can vary from 10 to 50 cm. In general, panels with a product width of 10 and 12.5 cm have a visible connection. Lamellae 25 cm wide are considered to be the most popular, with their installation almost no visible docking points are created. 300 and 375 mm wide panels are used as a finishing material for any surfaces, but they must be at least 10 mm thick.

The thickness of the products depends entirely on their purpose. Ceiling lamels have a thickness of from 5 to 8 mm. For such products strength does not matter. Wall building materials have the greatest thickness (10 mm), in contrast to previous variations, because they must resist mechanical damage and exposure to UV rays.

To attach and secure panels, manufacturers make PVC profiles that correspond to the parameters of the slats. The length of such profiles varies from 270 to 600 cm.

Kinds

Depending on the parameters, PVC lamellas come in several varieties.

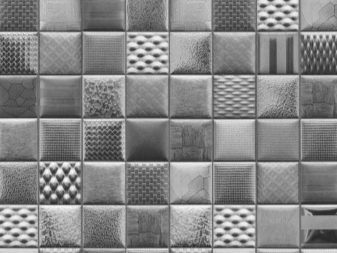

Tiled

Tiled material looks like ceramic tiles. The standard dimensions of this product are 30x30 cm, 98x98 cm, 100 x 100 cm. Their thickness is from 1 to 5 mm. Tiled panels can be used in combination with monochromatic variations of tiles that imitate natural stone.

Wall

Wall slats are used for decorating wall surfaces. Thanks to a large range of products, it is possible to create an original image in the interior of the room. The width of products varies from 15 to 50 cm, the value - 2.6 m, 2, 7 m, 3 m, thickness - from 6 to 10 mm.

Leafy

These panels differ from previous variations in large parameters.When working with this type of product a large area of the working surface is covered. The standard width of the slats is 50-122 cm, the value is 0.9 -2.44 meters, the thickness is 1-6 millimeters.

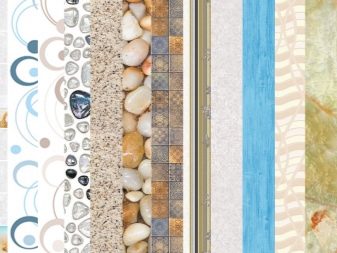

Sheet products often imitate various materials:

- tree;

- brick;

- mosaic;

- tile.

Clapboard

This kind of plastic products has a polished surface. Manufacturers make lining of various color shades and textures. The connection of products is carried out by means of the existing spikes, with the result that even an inexperienced master can perform the mounting. Width of products - 10-30 cm, size - 90 cm - 3 m, thickness - from 4 to 8 mm.

PVC lining is made in 2 variations:

- "Lining" - a product of a standardized size with a wide locking design. Width - 10 cm, width - 3 m.

- "Polka" - a product of standardized size with a narrow locking system. Length - 3 meters, width -10 cm.

Polyvinyl chloride wall panels also differ in connection method:

- lamellas with relief coating;

- seamless plastic building materials;

- panels that are chamfered.

Seamless finishing materials are usually used for covering the ceiling in various rooms. With a correct installation, you can achieve an effect in which the joint between the parts will be almost imperceptible. The seamless bonding method allows you to create continuous lines and patterns when covering various surfaces.

Bevel panels are somewhat similar to seamless products. The only difference is that in the first version there is a chamfer in the end part of the building material. A chamfer is a recess designed to connect plastic panels into a single unit.

Lamels with a relief surface are usually used for finishing wall surfaces. In appearance, they are similar to clapboard. Relief products differ from the previous variations in high strength and wear resistance. Due to such technical characteristics, they have a high cost.

PVC panels are available in a large number of colors and a variety of textures.

With 3D effect

This type of product is used not only in the design of residential buildings and apartments, but also in office buildings and shops.The original drawing allows you to create a unique design in the room. Lamellae with this effect imitate natural wood, natural stones, ceramic tiles. Standard parameters: width - 25 cm, 37 cm, 50 cm, size - 2.7 m, 3 m, thickness - from 8 to 10 mm.

Thermally interpreted

Manufacturing technology of this type of products is carried out in such a way that an image or pattern is displayed on the polymer film, after which the specialized equipment transfers this image under the influence of high temperatures to plastic building material. Thermal translation panels are considered to be the most popular among homeowners, because they have a high indicator of strength to the effects of high temperatures, and the installation does not deliver much difficulty even to a novice builder. The width of the panels - 25 centimeters, size - 2.7, 3 and 6 meters, thickness - from 8 to 10 mm.

Laminated products

The method of manufacturing laminated panels is that a film with an image and dressing is glued to the front. Such a manufacturing method gives the finishing material additional performance characteristics; such a drawing or image is rather difficult to spoil.Laminated panels are treated with antiseptic, which does not allow small particles of dust to settle on the surface of products. The quality of the panels of this type is certified by the appropriate quality certificate. Width - 25 centimeters, size - 2.7 and 3 m, thickness - from 8 to 12 mm.

How to calculate the right amount?

Before proceeding to the calculation of the required amount of building material, you need to know the perimeter of the working surface, on which the PVC panels will be installed later. After the total perimeter of the need to calculate the area of existing openings, then the resulting difference must be divided by the perimeter of a finishing product.

Consider an example of where the external lining of the walls of a one-story building with an area of 6x8 meters and a height of 2.5 meters with PVC lamellas will be carried out. This room has 4 window openings and 1 door. In this case, polyvinyl chloride panels with parameters of 2.5 x 30 cm will be used.

The total perimeter of the wall surface: (6 + 6 + 8 + 8) x2.5 = 70 m2.

We calculate the difference between the total area of the building and the openings of the room: 70-10.62 = 59.38 m2.

The area of 1 PVC product: 2.5x0.3 = 0.75 m2.

Calculate the required number of panels to work: 59.38 / 0.75 = 79.17 pcs.

The resulting number should be rounded up.As a result, 80 pieces of PVC panels will be required for the cladding of a one-story building.

When buying plastic decorative panels, it is necessary to take into account not only the parameter of the room, but also the method of their laying. It should take into account the price category of parts, because the long panels are significantly different from short lamellae, but, in turn, this does not affect the quality of the products. Also, when finishing the walls, decide on the thickness of the finishing building material, because the thicker the panels, the better the sound and thermal insulation will be produced in the room.

Recommendations for working with plastic

Before mounting the finishing product, it is necessary to stand the panels in the room where such installation is required. The product must acclimatize. This is necessary so that building materials are accustomed to the temperature in the room.

In addition to finishing materials, additional elements will be needed:

- inner corner;

- initial profile;

- finishing profile;

- plinth

Installation begins with a corner of the room in the direction of the window or doorway. The first is mounted inside corner. Slats need to be cut to the desired size, and the plates are cut depending on the method of installation.

The plastic product is inserted into the angular profile and mounted on the batten. For this purpose, you can use a construction stapler, but cleats are considered the best variation. They are installed in the lower area of the groove, and fasteners are made through a hole in the cleat. This method of fastening does not deform the plastic product, but also provides one hundred percent fixation of building material. Fasteners are selected at the rate of 2 dowels per 1 meter of profile and 2 self-tapping screws with large caps per 1 meter of PVC lamella size.

Subsequent elements are mounted using the “thorn into slot” method. At the same time, the panels should fit as closely as possible. At the end of the cladding, a joint forms between the wall surface and the floor, which must be closed using a plinth. For sealing joints on the ceiling, a more decorative ceiling plinth is used, which should be in harmony with the general trim of the ceiling.

The number of baseboards is calculated based on the total area of the ceiling. The standardized size of the plinth is 3 meters. The total perimeter of the ceiling surface should be divided by the amount of plinth, after which the resulting value is rounded up to a number that is a multiple of 3.

Work with plastic products can be carried out at a temperature of from -5 to +50 degrees, so wall decoration in baths and saunas is not performed. In places where there are switches and sockets, you must first install special boxes and hold electrical cable. When installing lamellae, it is necessary to cut openings for switches and sockets.

There are 2 methods of fastening plastic products:

- on the crate;

- on the adhesive solution.

Installation of lining or sheet panels can be carried out only on the frame. This is due to the large dimensions of the products. The frame in this case can be made of wood or metal slats. The height of the frame depends on the number of irregularities on the working surface.

Plastic construction materials in the form of tiles are mainly attached to the glue. In this case, it is necessary to carry out preparatory work. The surface must be cleaned of various contaminants, evened and treated with special means. They glue tile panels as tightly as possible so that no voids form under the products.

Pro tips

When choosing this finishing product, experts advise to pay attention to the following nuances, which will help you decide on the quality of the selected products:

- Initially, you must inspect the surface of the product. In perfect condition, it should have a smooth surface without flaws. There should be no gaps in the stiffeners inside the material.

- Connect several elements, while the connection should be made with ease and without the formation of seams. Quality products are assembled without much difficulty.

- When you click on the slat should not form cracks and dents. Pay special attention to wall products, which according to the norm should be characterized by a high indicator of strength.

- Also check plastic material for bending. If the product is not cracked or broken when bent, the product is considered to be of high quality.

- If you do not have experience with plastic products, it is better to purchase expensive products. In this case, work with such products will be more simplified. Working with cheap products, there is a risk of moisture getting inside the whole structure, which will further lead to deformation of products.

- Plastic panels are installed perpendicular to the direction of the frame rails.

- If you use panels with a pattern or pattern, then installation should start from the left corner to the right.

- Between the finishing elements must be left a gap of 5 mm. This is necessary so that when the temperature in the room increases, the plastic may change in size.

- When finishing walls in rooms where prevailing high humidity (bathroom, toilet), ventilation holes should be made, otherwise moisture will accumulate under the structure, resulting in mold and fungus.

Beautiful examples of finishes

PVC decorative panels today are considered the most popular among buyers. After all, thanks to the lining of various surfaces with such products you can independently create a unique look in the interior.

Bedroom

The bedroom requires soothing and relaxing shades, so in this case it is necessary to choose panels of light shades. It is not recommended to use glossy surfaces with a reflective effect. Such a design will only bore the owners. An excellent option is to finish the walls with panels that mimic the wood.You can also sheathe one of the walls in the room, with all the attention paid to it.

Bathroom

If you decide to decorate the walls and ceiling with plastic products, then be careful with the color solutions. It is undesirable to use more than 2 shades in this room. Also, it is worthwhile to abandon too defiant color solutions, rather choose neutral colors (gray, beige, white).

In this case, choose seamless types of products so that moisture does not get into the structure, thus you will prevent the occurrence of mold and mildew. Tiled plastic panels can be used in the bathroom in combination with natural stone. For a large room there is the possibility of using sheet products that mimic a mosaic.

Kitchen

Usually the PVC finish in this room is used by owners in those places that are subject to constant pollution (above the sink and washbasin). Also here it is appropriate to use zoning. Thus, you can select the dining area in the room. If the kitchen set is made in light shades, you can use bright shades of the finishing product to dilute the boredom in the interior.When making the ceiling with PVC panels, you can install built-in spotlights or lights.

For information on how to choose a quality PVC panel, see the following video.