Choosing machines for airing greenhouses

Growing plants in greenhouses is a rather complicated process, which has a lot of features and subtleties. In fact, it is not for nothing that the “battle for the harvest” is called, since there will be many difficulties to overcome for growing greenhouse vegetables. One of the problems may be the temperature regime: too low or too high temperatures are bad for any plants. The same will apply to high humidity. Therefore, you should talk in more detail about such things as automatic systems for airing greenhouses, which help to quickly solve the above problem.

Advantages and disadvantages of using

If we talk about automatic options for ventilation of greenhouses, they receive energy from the centralized power supply system or can be autonomous.

In other words, they fall into two broad categories:

- independent solutions;

- volatile options.

If we talk about the merits of the system of automatic ventilation of greenhouses, then it should be called:

- high processability;

- compact design;

- airing of the room is carried out in the stated time frame;

- high power.

The disadvantages of this mechanism will be the following points.

- If a breakdown occurs in the machine, the plants that are inside the room will die. To avoid the likelihood of such an outcome can be, if you buy in advance a spare electrical unit.

- If a breakdown of a structural element is detected, the entire system will need to be repaired.

In general, despite the presence of certain drawbacks, such mechanisms have indisputable advantages, which really make it possible to make an enhanced or conventional automatic ventilation machine an effective solution for growing plants.

Kinds

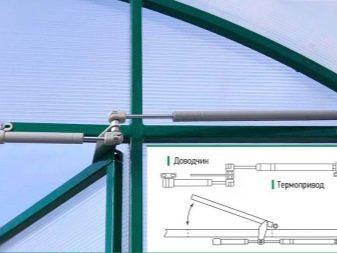

We now turn to the types of automatic installations for airing. As already mentioned, such mechanisms are divided into independent solutions and volatile autotype options.Volatile solutions cause great interest today. As a rule, the essence of such systems is to work from the mains and less often - from solar-type batteries or some other alternative energy sources. Such devices are usually used to operate a thermal switch that can activate the fans, providing fresh air to the greenhouse.

Independent decisions, in turn, fall into three categories:

- based on pneumatics;

- bimetallic;

- based on hydraulics.

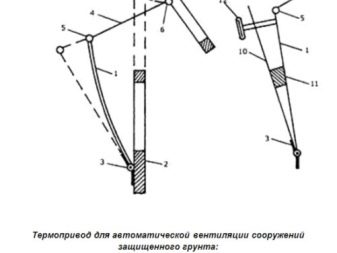

Now we analyze each machine more carefully. The bimetallic version for greenhouses works according to the following algorithm: when exposed to a certain temperature, the linear type material expands. This design provides for two types of materials, and the essence of the work consists in different coefficients of their expansion. That is, when the temperature rises, the thermal actuator in auto mode opens the vents and doors in the greenhouse, and when it goes down, it closes them. Automation in this case has only one drawback - it is difficult to choose the required temperature so that the ventilation is carried out with high quality.

Hydraulic option for ventilation of greenhouses has a number of advantages:

- no unpleasant odors or their minimum amount;

- lack of dependence on electricity;

- easy to assemble yourself;

- there is no need to constantly be near the greenhouse;

- the ability to work inside under comfortable conditions.

Such a system is considered one of the most reliable.

It should be noted that the mechanical mechanism for hydraulic ventilation also has some disadvantages:

- large inertia;

- high price;

- temperature can only be traced where the system is located.

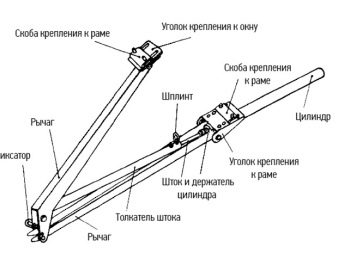

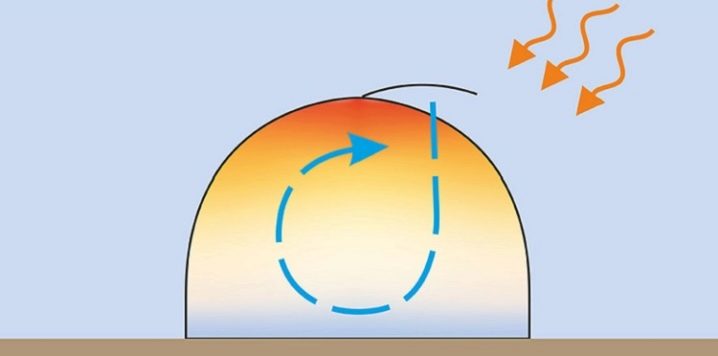

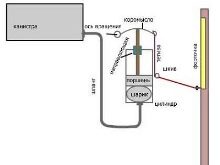

This machine has a fairly simple device. The hydraulic cylinder begins to move exclusively when there is a difference in the temperatures of the oil and the capacitive material. That is, it turns out that the stock is gradually being squeezed out. And it is the hydraulic drive that will open the window. To obtain optimal conditions in the greenhouse, allowing you to effectively take care of the plants, you just need to set a certain temperature. The door machine itself opens the door when the temperature gets higher than planned.

The system moves to the initial position only when the ventilator for dome vents or doors receives information that the temperature in the greenhouse is at the bottom mark.

Before buying a hydraulic universal ventilator for greenhouses, pay attention to the following points.

- Cost These machines are required for each window and door in the greenhouse. The price of one unit of construction will be about three and a half thousand rubles.

- Power. You should know exactly what power is needed to lift one or another element in the greenhouse.

- It is also necessary to know the weight of the machine that can withstand the greenhouse design.

Pneumatic version uses thermal energy. Its main advantage will be that it is completely independent of any other energy sources.

Among other advantages of this option should also be called:

- serious performance;

- low price.

It has several disadvantages, namely:

- small work effort;

- greater inertia;

- dependence on atmospheric pressure;

- cumbersome.

There are also electric models of autoventingers for greenhouses mentioned above.

Such systems are very convenient for the reason that they have:

- excellent electric drive power;

- accurate and convenient adjustment system.

They are perfect for greenhouses, where there is a need to use complex and multi-stage ventilation systems. The main elements of such systems are the thermal regulator, which is responsible for switching off and on the system, as well as the electrical ventilator. The main disadvantage is, of course, dependence on the availability of electrical energy.

In general, as you can see, there are many options for ventilation systems for greenhouses, and each person will be able to choose the most effective solution for their greenhouse.

Manufacturers

Now we will make a small review of products for airing greenhouses from various companies. On sale today presented a number of automatic devices that operate on various principles mentioned above. Any model that will be described is fairly easy to install yourself.But if we are talking about electrical solutions, it will still be better to contact a specialist.

"Dusya Sun"

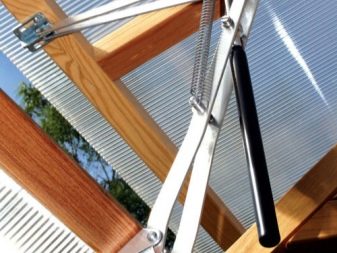

So, the first option, which I want to say - "Dusya Sun". This option uses a thermal cylinder that operates on the hydraulic principle. This model works at a temperature of not more than fifty degrees. The mass of the largest vents that this device can open is seven kilograms. The automatic machine is on sale in a full complete set, in addition to it there is an assembly instruction.

Installation can be performed in various greenhouses. The main thing is that the window leaf clearly works both at closing and opening. The discoverer does not need batteries or an electrical connection. The vent in this case can be easily configured to open the vents in the desired temperature range. If the temperature rises to 30 degrees, then the window opens to the end.

"Sesame-M-2015"

Another interesting option is called "Sesame-M-2015". The main element of this system is a hydraulic cylinder filled with oil. This model is applied in a wide range of temperatures and can be easily customized.The mass of the product is only one kilogram, but this is enough for the thermostat to easily open heavy vents of overall dimensions and doors. To avoid false triggering of the system from overheating, you can protect it by installing special umbrellas from the street.

If you need to leave the door in the open position, for this there are special hooks. This option requires almost no maintenance during use - it is only necessary to occasionally lubricate the mechanism with machine-type oil.

"Thermo"

The next model - "Thermal". This development of a domestic manufacturer from Krasnoyarsk can open a window or a door weighing up to twenty kilograms. But it is better to use it on window and door structures weighing up to ten kilograms. The largest opening angle is 45 degrees.

This design works using a hydraulic cylinder of a hydraulic type. The manufacturer gives a twenty-year warranty on their products. It is quite simple to carry out the installation of such a system with your own hands - the manual contains a similar installation scheme for this model.

Open planet

Another solution that you want to talk about is called Open Planet. The manufacturer guarantees that this device creates an ideal microclimate for plant cultivation in the greenhouse. Thanks to him, the temperature in the greenhouse can be adjusted in the range from 15 to 25 degrees.

This model has a reinforcement structure with two springs, which makes it possible to apply it not only on the vents, but also on the doors. Made autovent stainless steel. But for the cold season it is better to dismantle it so that the cylinder does not deform.

Airing circuits

Now let's talk about how to develop schemes for the automatic ventilation of greenhouses. This moment is very important, as the yield of plants and their comfort depend on it. With large volumes of space, usually rather complex device circuits are used, which take into account the value of various characteristics to the maximum. However, such an auto system for airing greenhouses will not be so pressing for a not very large home-type construction.

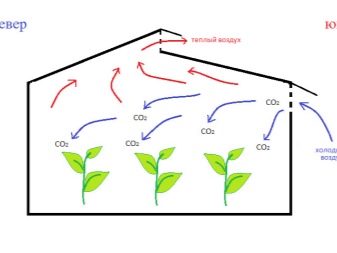

Good ventilation of the room can be ensured by correctly combining the periods of opening and closing of windows and doors with each other.

The most common schemes include the following:

- one-way airing - through two or more windows, located near, or transom;

- pass-through - two simultaneously open windows or doors located on different sides of the building;

- independent - each element, equipped with the necessary equipment, opens regardless of the others;

- mechanism connected to the control unit, which will take into account several parameters depending on the settings and characteristics of the equipment, and which works according to a specific algorithm.

The selection of different ventilation mechanisms will depend on the type of construction, as well as on the goals that the greenhouse owner will pursue.

How to do auto-checking?

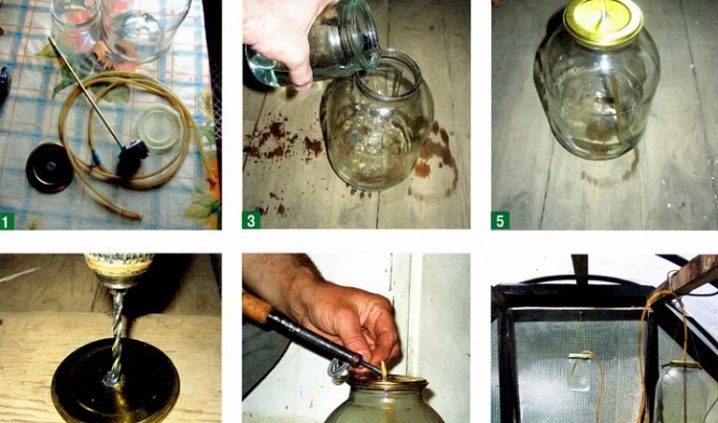

Now let's talk about how to create the system in hand. The basis of the simplest design will be two ordinary glass jars for preservation. One bank will have a volume of three liters, and the second - 800 milliliters.

In addition to them, we will need:

- one tin cover for seaming;

- polyethylene cover;

- thirty centimeter pipe made of copper or brass;

- tube for dropper meter length;

- a wooden bar, the dimensions of which should be equal to the dimensions of the window leaf;

- a pair of "weaving" nails;

- thin wire or a piece of rope;

- tin and rosin.

If we talk about the algorithm for creating the ventilation system, then it will consist of 3 main stages.

- First you need to pour into a 3-liter bottle of eight hundred milliliters of water and roll it with a tin lid. Then a hole is drilled in the lid, and a brass tube is inserted into it in such a way that about 2-3 mm is left to the bottom. The hole is carefully sealed with a sealant, solder or other means.

- Carefully make a hole in the plastic lid and push the flexible tube into it so that the distance to the bottom of the small can is the same as in the first case. Reliably seal the hole and close this lid with a small jar. The finished design is the simplest siphon of the pneumohydraulic type.

- Now it only remains to place the containers in different parts of the greenhouse, and also attach the counterbalance timber to the frame. After that, the mechanism will be ready for operation.

Such a simple and convenient to use design was created in 2000 and since then has been successfully used in a variety of greenhouses.The essence of her work is quite simple and consists in the fact that with increasing temperature, warm air gradually displaces water from a larger jar to a smaller one. Its mass becomes larger, and the window, respectively, opens. And with a decrease in temperature indicators, a large cylinder will “pull out” the water back, and the transom will, due to the presence of the counterweight, restore its original position.

Such a simple and at the same time reliable option will be suitable only for transoms that open along the central axis horizontally. By the way, the opening angle should be limited to a special type of stop. Once in a couple of weeks in a large cylinder is required to add a new liquid, instead of the one that has evaporated. In general, as you can see, choose a machine for a greenhouse - the process is quite interesting and requires serious attention.

To make such a device with his own hand also will not be any difficulty, if you strictly follow all the instructions. To do this, you can often use the available tools, and the proposed option can be adjusted and upgraded at its discretion.

In the next video you will find a brief overview of the automation for ventilation of greenhouses.