How to choose a mill for lining?

It is time for vacations, and with it the frequency of country trips to the cottages increases. There, a craftsman always has something to lend a hand, giving free rein to a creative start in construction and repair. An indispensable material for wall decoration is practical lining, made by hand.

Species

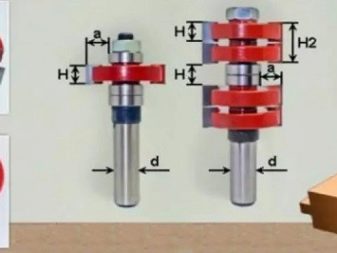

The choice of milling cutters for lining is determined by production objectives and economic feasibility. Milling equipment has a different power, so it is equipped with different types of models that differ in shank diameters of 8 and 12 mm.

All types of structurally can be divided into several groups:

- teams with mechanical fastening knives;

- with soldered blades;

- monolithic.

Prefabricated models have several advantages, but are the most expensive. Changing plates for carbide or high-speed steel and using the same set, it is possible to work with wood of different density. Knives are sharpened, and when the production resource is exhausted, the knife itself must be replaced, and not the entire mill.

Among the models with soldered plates, the most popular are the so-called backed up. They have less cost compared to the first. Due to the process of cutting on the front face, when regrinding the working profile does not change. This is the main advantage of such specimens, along with the ease of regrinding. In addition, their teeth have increased strength. When regrinding, the size of grooves for outputting wood chips increases, which is convenient in operation.

Most often in the ground models, brazed plates made of high-speed steels are used. For example, Р6М5 (HSS). Foreign-made high-speed alloy is marked in accordance with international standards by the abbreviation HSS (High Speed Steel).

For the production of cladding material choose soft or medium density wood species. Conifers - spruce and pine, broadleaf - linden, alder.Therefore, the choice of high-speed alloy is not accidental.

A more expensive class has solder plates on hard tungsten alloy discs. In particular, domestic alloys VK8, VK15 (tungsten and cobalt). Foreign-made solid alloys are designated in accordance with ISO as HM (Hard Material), which means solid metal. Other name - Solid carbide. This type behaves well when cutting large volumes of solid wood - oak, ash, beech.

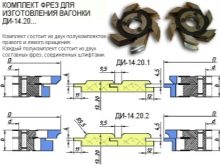

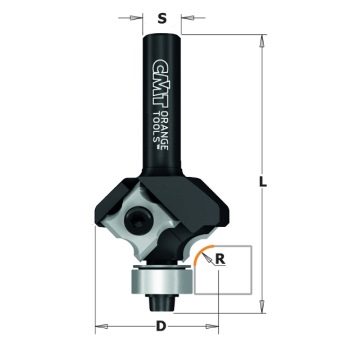

A typical mill for lining consists of the following elements:

- structure axis with fastening nut;

- two disks with knives;

- bearing located between the cutting blades.

Often it is advisable to disassemble them in order to replace any component. Knives made of hard tungsten alloy VK8 (tungsten and cobalt) can be sharpened up to 4 times.

Verified Manufacturers

Today in the construction industry there are hundreds of small and large firms. Experts recommend carefully examine all the nuances before contacting any of them.

Set of end mills "Globus"

The company has established itself as a bona fide professional tool manufacturer.Trailer mills of the Globus firm are intended for manufacturing of such products as lining, a block house, eurolining. Two combined elements are included in the package, the catch profile. This set is good because it allows for two passes to make a full rail lining, which can significantly reduce the time and labor costs.

At all levels between the bearings, the discs and the nut, there are mounting gaskets, thanks to which it is possible to easily adjust the clearance between the discs. This will help adjust the clearances or tension of the thorn-groove connection. Carbide soldering soldered very high quality, without sagging, the flow of brass, performed carefully.

Inveld

The company has been making carbide tipped cutters for over 20 years. One of the latest developments of the company is a kit for the manufacture of eurolining or just lining. The kit consists of two elements. One cuts the front part, and the second makes the mating part.

The set comes in two types of configuration. The first version - with a shank of 8 mm. The second - with a shank of 12 mm. This was done with the aim of working both on milling machines with low power and on more powerful equipment - milling machines. The design is folding.You can loosen the mounting nut and remove the components, replace the bearing or sharpen knives. Knives carbide, alloy VK8. Brazed to the shaft with brass. They are easy to sharpen yourself with a diamond tool on the back of the knife.

"Slavic court"

This manufacturer produces options for quadrilateral and milling machines.

The company "Slavic yard" supplies a wide range of models. They are intended for the production of all types of cladding boards (for timber, clapboard, eurolining, American, block house). You can choose a suitable type for yourself in a set or separately. With replaceable or napaynymi knives.

Manufacturing process

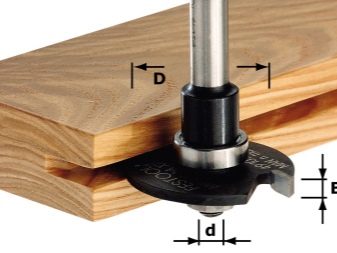

Lining is a well-treated board that has been smoothed out of roughness, with a groove on one side and a tongue / tongue for a joint on the other. The design is quite simple, so there is nothing possible in making it yourself.

For this you will need:

- hand mill or machine;

- set of cutters;

- the boards.

For the production of lining need stripped fugovannye boards. Such blanks can be made independently or purchased ready-made.Making personal blanks, it is better to take short boards (up to 2 m). They are easier to manage and the result will be more accurate. First you need to cut the raw board on one side, and then measure the desired size from a smooth edge. The optimal width is 7 - 10 cm, although all this is at the discretion of the master.

To get the same thickness of the future lining, you need to withstand the number of passes through the mill. The resulting difference of a few millimeters will be visually imperceptible.

Having prepared the tree in this way, we proceed to the next stage. It is necessary to cut out a thorn and a groove along the perimeter of the board.

On the machine it happens in several stages.

- The selected milling cutter is installed on the machine.

- Lowering or raising the table adjusts the depth of the groove.

- At the specified distance set ruler. During operation, it is necessary to ensure that the workpiece fits snugly to its edge, otherwise the size will fail.

For the production of lining hand mill requires a calibrated board. To make it on a manual mill will not work, the surface gage is required. The width of the ridge should be 4 - 6 mm. The thinner one will break off, and the Klyimer will not take it thicker. It is made face mill.Then the framed pass from above and remove the residue so that the flat area is at least 5 mm. On the other hand, a smaller chamfer is removed. It is also necessary to monitor the thickness of the material in order to obtain an even product.

Operation Tips

Working with a router can be traumatic, so you need to clearly know and follow the rules of operation of the equipment. And then the manufacturing process will not bring unpleasant surprises, but it will be a joy.

Manufacturers give simple tips to extend the life of the cutter.

- When working with wood, tar deposits accumulate, which leads to premature wear. Therefore, it is necessary to clean the instrument daily from plaque.

- Do not start to work with a blunt tool. The lack of sharpening can provoke the burning of the cutting edge and the occurrence of an unrecoverable defect on the working surface.

- Follow the rules of sharpening. In the models that have been ground out, it is performed on the front face of the cutting tool with the stones CM1, CM2, with a grain size of A25 or A35. Sharpening knives made of carbide materials make diamond circles. Do not forget to ensure that there is no burning edge.

As you can see, the process of manufacturing lining is not particularly difficult. He is under the power of any interested person. Do not be afraid to start a new business, and then the result will not take long.

How to choose quality cutters and what are their differences, see the following video.