Mixer bar: rules for selection and installation

The strap for a mixer is a necessary element of the design of most modern mixers and serves to securely fasten parts of the pipeline to the wall.

Device and purpose

Mixing strips are metal or polypropylene devices consisting of one or two water outlets located at a right angle to the front surface of the structure. The inner part of the fittings is threaded, often made of brass and serves as a point of attachment for eccentrics. In the upper part of the element are holes designed to fix the strap to the wall. Their number can vary from 2 to 4 pieces and depends on the design and type of model. The lower part is equipped with pipe outlets. Mixing strips can be installed on all types of walls, including stone, concrete, cinder blocks and wooden bases, as well as plasterboard and gypsum fiber partitions.

They are made from iron, steel, copper and bronze alloys, as well as polyethylene, polyvinyl chloride and polybutene. The most durable and practical models are made of polypropylene and brass. Such products have high anti-corrosion properties, good heat resistance, ease of maintenance and installation, as well as strength and low weight.

They are able to withstand temperatures up to 90 degrees and tolerate the effects of household chemicals.

Classification

Mixing strips are classified according to several criteria.

- By type of liner the slats are lower connection and flow type. The first ones are a device in which the outlets for connecting the pipeline are located on the bottom. Such models can have both metal, and polypropylene execution and are a classical option. Flow types are two parallel pipes with knees fixed on them and are used in cases when the bottom connection of the mixer is impossible.

- The material of manufacture. The slats can be metallic and non-metallic. The first ones are intended for installation on a metal-plastic pipeline, the connection to which is provided by compression fittings.The latter are used in combination with pipes made of polypropylene, the connection with which is carried out using a special apparatus using butt welding.

- Constructively mixing strips are divided into three types.

- Universal strips are made in the form of a perforated metal bracket, through the holes in which the element is screwed to the wall and the water outlets are fastened. Such models are used for the installation of non-standard or home-made mixers, in cases when the center distance between the fittings is different from the standard one. The design of the slats and allows you to fasten the water sockets at a distance of 75, 115 and 155 mm from each other. Numerous perforations make it possible to install on them fittings with a central, straight and angular type of fastening. An important advantage of the universal strip is the ability to install it on the wall using a flush-mounted installation. This allows you to hide the case parts in the wall and frees the interior of the bathroom from excessive clutter of pipeline elements.

- The simple mounting plate is made of metal, has two holes for fastening and is equipped with two holes for standard fittings with a typical distance between them.

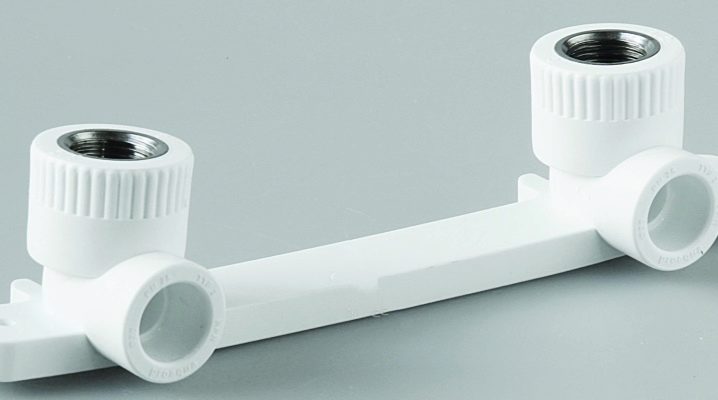

- The third type of products is represented by models for PVC pipes and is a single or double construction in which the water outlet is pressed into the plastic case. Such strips are completely ready for installation and do not require self-assembly. Water sockets in such slats are fully compatible with mixers made in traditional sizes, where the distance between the axes of the nuts corresponds to 150 mm, and the dimensions of the main pipes and their connections are equal to 20x1 / 2 and 25x1 / 2. Thanks to this design feature, there is no need to center the connection points, and there are no problems with the installation of the planks.

Types of water sockets

Water sockets, installed or already available on the mixing planks, also divided into several species.

- Threaded fittings are connected to pipes by means of thread and are distinguished by durability, ease of installation, good tightness of the connection and impact resistance.

- Crimp water sockets are connected to the pipeline using a special sleeve installed between the outer and inner part of the fitting and called the "collet".This type is characterized by low cost, long service life, fast installation, the possibility of re-disassembly-assembly and high tightness of the connection.

- Opressovochnye sockets are connected to the water supply by soldering, performed by a special device. Models are characterized by versatility, low price, reliable connection and small size.

- Self-locking water sockets are made of brass and are attached to the mixing bar with rivets. Models are easy to install, dismountable device, reusable and durable connection.

Subtleties of installation

The installation of the mixing bar should be carried out during the renovation of the bathroom. This is due to the need of shtabirovaniya walls under the pipe, which is a prerequisite for the drowning slats. In cases when it is impossible to hide the bar, it is fixed directly on the wall. Collapsible types of products of simple and universal type are assembled prior to installation. To do this, you should install water sockets on the bar, without tightening them and checking the conformity of the center distance between the fittings with the center line.mixer distance. Making sure that the structural elements are fully compatible, the water sockets can be tightened.

When installing the device under a plasterboard partition, the fixation of the strip is made on a wooden plate, which is strengthened between the profile guides, or on a bar rack, pre-installed in a pocket at the desired height. The thickness of the wooden strip is calculated so that the plank placed on it is completely located in the recess, and the ends of the fittings are in the same plane with the wall surface.

After the plank is fixed, install an external sheet of drywall and in the necessary places form holes for eccentrics.

To install the mixing bar on brick or concrete bases, at the place of fixing the device, you should hollow a niche 4–5 cm deep, then mark and outline the location of the bar with marked places for mounting holes. The markup is recommended to use the construction level, which will help to place the device in a strictly horizontal position.Then, small pieces of straight pipes necessary for leveling the bar when tightening and preventing the solution from getting into the fittings during the subsequent filling of the niche should be screwed onto both water sockets. After the plank is installed, it is necessary to once again check its location with a level and putty on the pocket with a thick solution. After complete drying of the filler mixture, you can install the mixer.

Mixer bars are an integral part of the water supply system. They help to quickly replace a failed mixer and greatly simplify the installation of the pipeline.

How to choose?

When choosing mounting strips, many have a question, it should be purchased together with a mixer and a water outlet or separately, adjusting the size.

When buying, you should be guided by the following criteria:

- the holes that are used for fixing the water sockets should coincide with the perforation of the plank;

- the gap between the sockets should correspond to the size of the mixer.

Mounting strips under the mixer - in the following video.